Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

Power tools are essential in industries like metalworking, woodworking, construction, and automotive repair, helping professionals and DIY enthusiasts achieve precision and efficiency. Among the most common tools are Electric Die Grinders and Angle Grinders, each serving different purposes based on the job.

An Electric Die Grinder is compact and designed for detailed, precision tasks such as grinding, polishing, and engraving on smaller surfaces. In contrast, the Angle Grinder is a more powerful tool, suited for heavy-duty applications like cutting, grinding, and polishing larger surfaces or tougher materials.

Understanding the differences between these tools is key to selecting the right one for your needs. Whether you're working on a fine woodworking project or cutting through metal, choosing the right tool ensures optimal performance. In this article, we compare the Electric Die Grinder and Angle Grinder to help you choose the best tool for your next project.

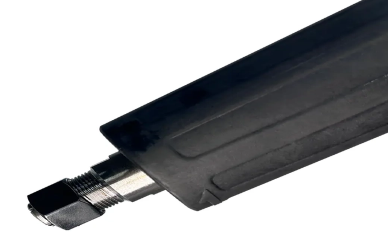

An Electric Die Grinder is a high-speed, handheld power tool designed for precision grinding, polishing, sanding, and other detailed tasks. Unlike larger tools, such as angle grinders, die grinders are more compact and designed for fine, intricate work. They are powered by electricity and typically feature a rotating spindle that holds a variety of attachments. This allows users to perform a range of tasks on different materials, including metal, wood, and plastic.

Electric die grinders are incredibly versatile tools, primarily used for detailed and precision tasks in industries such as metalworking, woodworking, and automotive repair. Some of the most common applications include:

Grinding: Shaping, smoothing, or removing excess material from small workpieces.

Polishing: Giving a fine finish to surfaces, often used in metal and jewelry work.

Sanding: Sanding down small areas or smoothing out rough edges on wood, metal, or plastic.

Engraving: Used for fine etching or engraving on materials like metal, plastic, and wood.

Deburring: Removing burrs or sharp edges from metal and other materials after cutting or machining.

Electric die grinders are much smaller and more compact than angle grinders. This size difference makes them ideal for precision tasks in confined spaces where larger tools would be difficult to maneuver. They are typically more lightweight and easier to handle, offering excellent control and agility for detailed work. Despite their smaller size, they can still deliver high RPMs (revolutions per minute), making them powerful tools for the jobs they’re designed for.

One of the key advantages of electric die grinders is the variety of attachments that can be used with them. These accessories enhance the versatility of the tool, making it suitable for a wide range of applications:

Sanding Drums: Used for sanding, polishing, and finishing surfaces.

Grinding Bits: Great for grinding, shaping, or removing material from hard surfaces like metal.

Polishing Pads: Ideal for giving a smooth and shiny finish to metals, plastics, or painted surfaces.

Cutting Discs: Used for cutting small sections of metal or other materials.

An Angle Grinder is a versatile and powerful handheld power tool commonly used in construction, metalworking, and automotive repair. It is designed for cutting, grinding, polishing, and surface preparation tasks. The tool is equipped with a rotating disc or wheel that spins at high speeds, allowing it to tackle tough materials like metal, concrete, and stone. Angle grinders are typically larger and more robust than other power tools like electric die grinders, making them ideal for more heavy-duty and rough tasks.

Angle grinders are used in a variety of demanding applications, making them a staple in many industries:

Heavy-Duty Grinding: Removing excess material, grinding down surfaces, or smoothing rough edges on large workpieces, often in metal fabrication.

Cutting: Using the right disc, angle grinders can easily cut through metal pipes, rebar, tiles, concrete, and stone, making them essential for construction and demolition work.

Polishing: When equipped with a polishing pad or disc, angle grinders can be used for polishing surfaces such as metal, stone, or concrete, providing a shiny finish.

Surface Preparation: Angle grinders are commonly used for tasks like rust removal, paint stripping, and smoothing concrete or stone surfaces in preparation for further work.

Angle grinders are typically larger and more powerful than electric die grinders, designed for more demanding tasks. They come in various sizes, with 4.5-inch to 9-inch discs being the most common. The larger size and increased power allow them to handle tough, high-impact jobs that require significant force and durability. These grinders are built to work on larger surfaces or tougher materials, such as thick metal or masonry, making them a go-to tool for professionals and heavy-duty tasks.

Angle grinders are highly versatile due to their wide range of interchangeable accessories, which enhance their functionality for different tasks:

Grinding Discs: Ideal for heavy grinding tasks such as smoothing or removing material from metal or stone.

Cutting Discs: Used to cut through hard materials like metal, concrete, and tiles with precision.

Polishing Pads: Attach to the grinder to provide a smooth, glossy finish on metal, stone, or concrete surfaces.

Wire Brushes: Used for cleaning surfaces, removing rust, and prepping metals for further processing.

One of the most noticeable differences between electric die grinders and angle grinders is their size and weight:

Electric Die Grinders: These tools are compact and lightweight, making them ideal for precision work in smaller spaces. Their design allows for easier handling and control, especially when working on intricate or detailed tasks such as engraving, deburring, or polishing.

Angle Grinders: In contrast, angle grinders are heavier and bulkier, built for larger, tougher tasks. Their increased size and weight make them better suited for tasks that require more force and power, like cutting through metal pipes, grinding concrete, or removing large sections of material.

The difference in power and performance is another critical factor when choosing between these two tools:

Electric Die Grinders: These are designed for lighter, more detailed tasks. They offer adequate power for small grinding, sanding, and polishing jobs but are not suited for heavy-duty applications. They provide the precision needed for delicate tasks without overworking the tool.

Angle Grinders: Angle grinders are more powerful and are built to handle tougher tasks, including cutting, grinding, and polishing large surfaces. With more robust motors, they can work on tougher materials such as metal, stone, and concrete, making them suitable for heavy-duty applications in construction or metalworking.

Another key distinction lies in the type of work each tool is suited for:

Electric Die Grinders: These are precision tools meant for detailed, fine work. They are great for small jobs like grinding edges, engraving, and polishing smaller or more delicate areas where control and accuracy are essential.

Angle Grinders: Angle grinders, on the other hand, are designed for heavy-duty tasks. They are perfect for grinding large surfaces, cutting through thick materials like metal and concrete, and performing aggressive material removal. They are built for larger, tougher jobs where speed and power are necessary.

The speed and RPM (revolutions per minute) of the tool can significantly affect the performance and suitability for specific tasks:

Electric Die Grinders: These tools typically operate at higher RPMs, making them faster for smaller, more detailed tasks. The high speed allows for fine, quick work on small areas such as grinding metal edges or polishing surfaces.

Angle Grinders: Angle grinders have lower RPMs compared to die grinders, which gives them more control over their grinding and cutting functions. This lower speed allows for more controlled cutting of tough materials like metal or stone without causing overheating or excessive wear on the tool.

An electric die grinder is perfect for precision tasks like engraving, polishing small parts, and deburring. Its compact size and high RPMs make it ideal for detailed work in confined spaces where control and finesse are needed.

Common tasks: Engraving, polishing, sanding, and deburring small areas.

An angle grinder is suited for heavy-duty tasks like cutting metal, grinding concrete, or surface preparation. It’s more powerful, making it ideal for large surfaces and tough materials.

Common tasks: Cutting metal, grinding concrete, polishing large surfaces, removing rust.

Confined Spaces: Die grinders are better for tight, intricate areas due to their compact design.

Large Surfaces: Angle grinders excel in open spaces, offering the power needed for heavy-duty tasks.

Specific Materials: Die grinders are better for delicate work on smaller materials, while angle grinders handle tougher, thicker surfaces.

Answer: While die grinders are primarily used for polishing and fine detail work, they can be used for light cutting tasks with the appropriate accessory, but an angle grinder is more suited for cutting thick metal or other heavy-duty materials.

Answer: The main advantage of an angle grinder is its power and versatility for heavy-duty tasks, like cutting, grinding, and polishing large surfaces or tough materials.

Answer: Yes, an electric die grinder is typically more precise due to its smaller size, higher RPM, and the ability to use finer accessories for detailed work.

Answer: Yes, an angle grinder can be used for polishing when equipped with the correct attachment, but it’s more suited for rough work. For finer polishing, a die grinder would give more control and precision.

In conclusion, the electric die grinder and angle grinder are both valuable tools, but they serve very different purposes. The electric die grinder is ideal for precision work, offering control and finesse for tasks like engraving, polishing, and deburring small areas. On the other hand, the angle grinder is built for heavy-duty tasks, such as cutting, grinding, and polishing larger surfaces or tough materials. When choosing between the two, consider the requirements of your project—whether you need fine detailing or rough, heavy-duty performance. For more specialized advice or specific product recommendations, it’s always a good idea to consult with experts or refer to product manuals to ensure you select the right tool for the job at hand.