Views: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

Electric die grinders are essential tools in a variety of industries, including metalworking, woodworking, automotive repair, and more. Known for their precision and versatility, these tools are perfect for tasks like grinding, polishing, deburring, and engraving. With their high-speed motors and compact design, electric die grinders allow users to work on intricate details and hard-to-reach areas with ease. Whether you're a professional or a DIY enthusiast, understanding how to choose the right electric die grinder can greatly enhance your work efficiency and the quality of your results. In this guide, we'll explore the different uses of electric die grinders, the types available on the market, and provide essential buying tips to help you make an informed decision for your next project.

Electric die grinders are commonly used for grinding and smoothing surfaces made from materials like metal, wood, and plastic. These tools are ideal for tasks such as shaping materials, removing excess material, or smoothing rough edges. Their high-speed motors and precision attachments make them effective for fine grinding work on small parts and surfaces.

These grinders are highly effective for polishing and buffing small or intricate parts, especially in metalworking and automotive applications. When fitted with the right attachments, they can deliver a smooth, shiny finish on metals, plastics, or painted surfaces. This makes them ideal for polishing small components, restoring shine, and achieving a professional finish.

One of the most common uses of electric die grinders is deburring, or removing sharp edges and rough spots from metal parts after cutting. This process is essential for improving the safety and functionality of metal components, ensuring there are no jagged edges that could cause damage or injury during use. Die grinders make quick work of deburring tasks, especially on smaller parts.

For precision tasks such as engraving designs or creating intricate artwork, electric die grinders provide the control and high-speed rotation needed for fine detailing. They are widely used in metalworking, jewelry making, and woodworking, where intricate designs and sharp details are required on various materials such as metals, wood, and plastics.

Electric die grinders can also be equipped with sanding attachments, making them perfect for sanding small areas or hard-to-reach spots. Whether you need to smooth wood edges, sand metal surfaces, or finish off delicate areas, the grinder's compact size allows for more control and access to areas other tools might not reach. This versatility makes die grinders useful for both large and small sanding tasks.

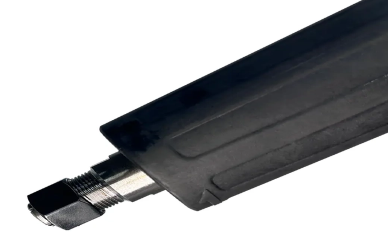

Corded electric die grinders are powered directly through an electrical outlet, providing a constant power supply. These models are known for their reliable performance and ability to handle continuous use without the need to recharge or worry about battery life. Corded die grinders are ideal for jobs that require extended operation, such as heavy-duty grinding or polishing tasks. Since they don't rely on batteries, they tend to offer more power and consistent RPM, making them suitable for both professional workshops and DIY projects.

Advantages:

Uninterrupted power for long tasks.

Consistent performance with no risk of running out of battery.

Better for heavy-duty work and high-torque tasks.

Cordless electric die grinders offer greater portability and convenience since they don’t require a power cord. Powered by rechargeable batteries, these models are lightweight and easy to maneuver, making them ideal for use in tight spaces or outdoor jobs. They are perfect for lighter tasks where mobility is essential. However, the power may be somewhat less than corded models, and battery life can limit extended use, requiring recharging.

Advantages:

Portability for use in locations without easy access to electrical outlets.

Ease of use in confined or hard-to-reach areas.

No need to worry about cord tangling or limitations of cord length.

When comparing electric die grinders to pneumatic die grinders (powered by compressed air), the primary differences lie in performance and application.

Electric Die Grinders: These are powered by electricity and are generally more convenient for everyday use, especially when a power source is available. They offer consistent torque and RPM for detailed tasks and are easier to set up and maintain compared to pneumatic models. Electric die grinders are great for DIYers and professionals who need portability and simplicity.

Pneumatic Die Grinders: Pneumatic models tend to be more powerful than electric grinders, especially for heavy-duty tasks. They are commonly used in industrial settings or high-demand environments, where constant high performance is needed. However, they require a reliable air compressor, which can limit their portability and flexibility in some settings.

Comparison:

Performance: Pneumatic grinders are generally more powerful and perform well for tougher tasks, while electric die grinders are more suited for precision and light to moderate tasks.

Portability: Cordless electric die grinders win in terms of mobility, but pneumatic grinders require an air compressor.

Maintenance: Electric grinders are simpler to maintain, while pneumatic models require more care in managing air systems and ensuring there’s a constant air supply.

Motor power affects performance by determining the tool’s torque and RPM. A powerful motor is essential for heavy tasks like grinding or deburring, while a less powerful motor is sufficient for lighter work like engraving or polishing. Choose a grinder with higher motor power for demanding jobs.

Variable speed control is key for precision. It allows you to adjust the speed to suit different tasks—higher RPM for finer work like polishing, and lower speeds for grinding or sanding. This feature gives you better control and reduces the risk of damage.

Comfort is crucial, especially for extended use. Look for a lightweight, well-balanced die grinder with a soft grip to reduce hand fatigue and improve control. An ergonomic design ensures comfort for long sessions and allows better maneuverability in tight spaces.

The chuck size determines the range of attachments you can use. A 1/4-inch chuck is most common and accommodates a wider variety of accessories. If you plan to use different attachments, choose a grinder with a chuck size that fits your needs.

Look for grinders made with durable materials like metal casings and reinforced housing. Quality internal components, such as motors and bearings, also ensure the grinder’s longevity and consistent performance over time.

First, think about the tasks you’ll use your electric die grinder for. If you’re working on smaller, detailed jobs like polishing, engraving, or deburring, you’ll want a tool with high RPM and fine control. If you're doing more demanding work—like grinding tougher materials—a more powerful model is better. Choose the grinder that fits your application, whether it’s light precision work or more intensive use.

Selecting a trusted brand for your electric die grinder can make a big difference in quality and reliability. Make sure to read customer reviews and check user feedback about durability, performance, and ease of use. A recognized brand often provides better replacement parts and ongoing support, which can help in the long run.

Expect to spend more for higher quality and better features in your electric die grinder. Entry level models may cover basic tasks, but if you need variable speed, better ergonomics, and longer lifespan, be prepared to invest more. Compare prices across models and weigh them against the features you need to ensure you get good value.

Warranty and support often differentiate a good purchase from a regrettable one. A solid warranty gives you peace of mind if something goes wrong, and reliable customer support means you’ll get help when it’s needed. When buying an electric die grinder, check the warranty terms and after sales service to ensure you’re covered for both performance issues and future maintenance.

Answer: Electric die grinders can handle light cutting tasks with the right accessories, like cutting thin metal or small sections. However, for heavy-duty cutting of thick metal or dense materials, an angle grinder is more suitable due to its higher power and cutting capacity.

Answer: To keep your electric die grinder in good condition, regularly clean it, lubricate moving parts, and check for worn components like brushes, bearings, and the spindle. Follow the manufacturer's maintenance instructions and replace worn parts promptly to extend its lifespan.

Answer: For small, detailed tasks, a 1/4-inch chuck size grinder is ideal. It offers better maneuverability and precision, making it perfect for engraving, deburring small parts, and sanding tight spots in confined spaces.

Answer: Yes, electric die grinders are great for sanding small areas, especially in hard-to-reach spots. By using sanding drums or flap wheels, you can smooth surfaces, remove paint, or finish details on metal, wood, or plastic. This makes them versatile for precision sanding.

In this guide, we’ve explored the essential aspects of electric die grinders, including their types, common uses, and key features to consider when purchasing one. From corded and cordless models to the comparison with pneumatic grinders, we've highlighted how each type can cater to specific needs, whether you’re handling light, detailed tasks or more powerful, heavy-duty jobs. We also discussed important features like motor power, speed control, ergonomics, and durability to ensure you choose a die grinder that aligns with your requirements.

When selecting the right electric die grinder, it’s crucial to consider the tasks you’ll be performing—whether it's engraving, polishing, sanding, or deburring. Carefully assess the tool based on its power, comfort, and versatility, and keep in mind the maintenance and accessory compatibility for long-term performance. By following the buying tips provided, you can ensure that you select the most suitable model for your projects, enhancing both your work efficiency and the quality of your results.